Everyday the health and wellness of workers are exposed to numerous risks that affect their working life. In 2015 just over 3.2 milion non-fatal accidents occurred in Europe relating to injuries , sprains, and strains, leading to general absenteeism of operators from their positions. (Source: Eurostat, “Accidents at work statistics“).

Among them, muskuloskeletal disorders (MSDs) is the most common occupational disease in Europe according to Eurofund’s report (2015), (Source: Eurofound, “Sixth European Working Conditions Survey – Overview report”), 61% of European workers are subject to repetitive movements of arms and hands, 33% to the moving of heavy items and loads, and 20% to the use of highly vibrating machines. This scenario predicts that fractures and dislocations are frequent and in most cases can affect the neck, shoulders and back.

It is important that companies ensure they actively pursue all the necessary requirements to preserve workers wellbeing, not only for health and safety reasons, but also to achieve productivity and optimum working levels.

That’s where Ergonomics comes into play.

What is Ergonomics?

“Ergonomics (or human factors) is the scientific discipline concerned with the understanding of interactions among humans and other elements of a system, and the profession that applies theory, principles, data and methods to design in order to optimize human well-being and overall system performance. (IEA,2000)”

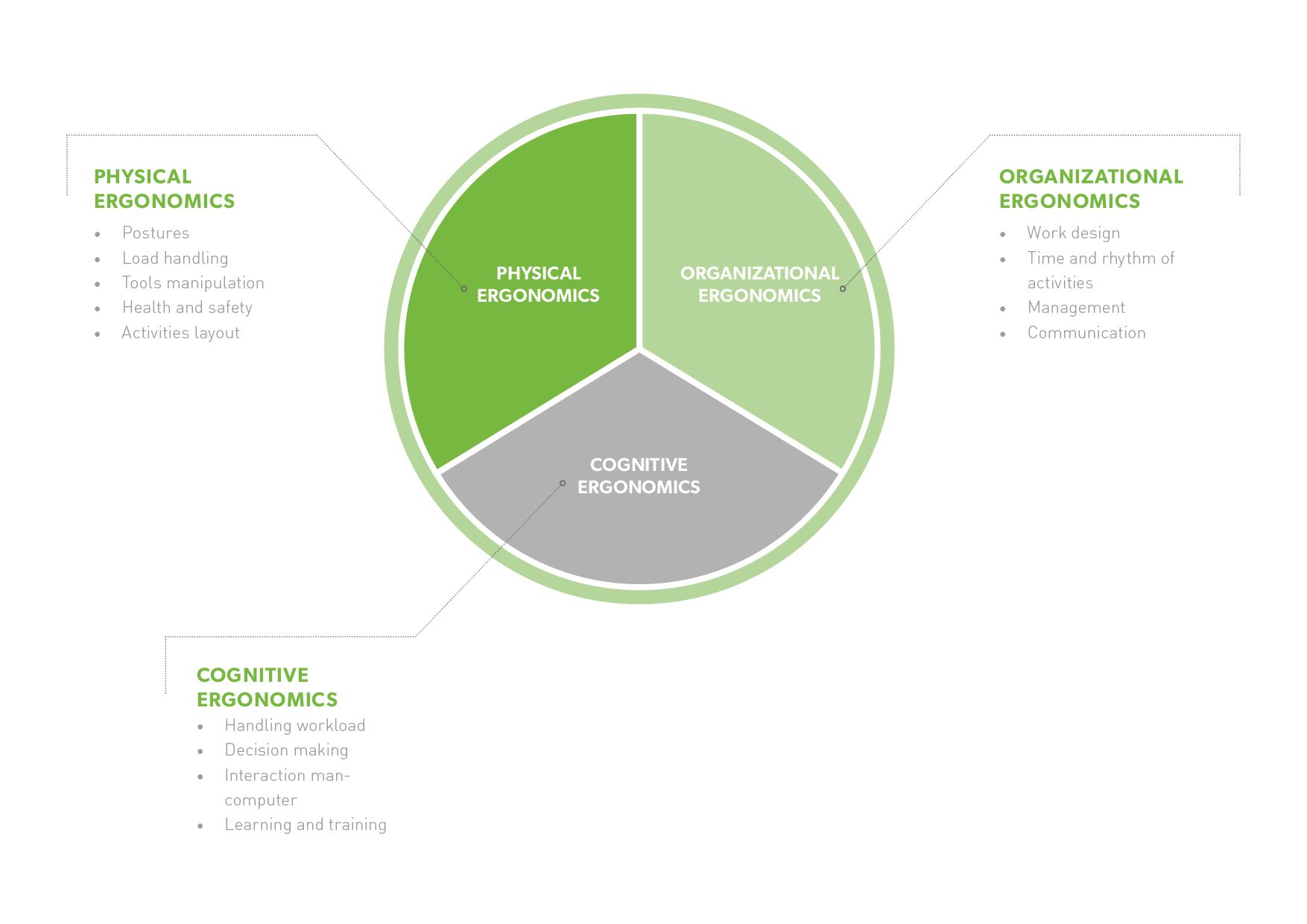

From Greek “ergo” (work) and “nomos” (law, rule), the science of Ergonomics studies all the work performance directly linked to the operation, use of equipment and the enviroment where a person act. It focuses attention on the interaction between the user and the products used in a specific system. In this regard, Ergonomics researchers approach their study from three different perspectives:

- Physical aspects: these involve the study of anatomic, anthropometric, physiological and biomechanical elements. All these elements deal with the relationship between people and the systems in place, focusing attention on the physical activities. These aspects are concerned with the study of the posture kept by people during their working activities, their handling and use of tools, health and safety, and activities.

- Cognitive elements: these elements are the study of mental processes, awareness and information processing as soon as human being interfaces with the system. The results of this study are an analysis of the logical consequences connected with the awareness of the stimuli, the understanding of signals, the activation of controls and the adjustements of systems, all of which are made by the operator.

- Organizational aspects: they relate to the optimization of socio-techinical systems, organized structures, strategies and politics which underlie users’ activities. This category encloses time, methods, work design, relationships, atmosphere and communication.

Concerning issues from a physical perspective, IPC Group noted the occurrence of a relevant discomfort by the operators due to the use of wringer handles, and in particular the lever, on some cleaning tools.

Starting with the analysis of some leading trolleys within the IPC range, the Group worked on the realization of the innovative wringer “KINETIC” with the aim of answering this question:

how to improve the lever through ergonomics?

Analysing some of the top IPC trolleys equipped with the wringer, it was pointed out that their use was causing:

- Incongruous wrist position;

- Rigid posture;

- Uncorrect use of the handle.

Owing to the evident discomfort shown by our staff and employees relating to the use of the wringer handle, IPC decided to improve and develop ordinary equipment in line with the most modern ergonomic international standards.

Concentrating on the design, the handle and the angle of tube folding, the attention was kept on the:

- Wring posture;

- Hand posture.

The goal has been to develop the use of wringer handle so that it becomes more practical and handy.

So, our KINETIC wringer now ensures a better and more efficient wringing of the mop:

- the handle position makes operations easier, allowing a more natural posture to the operator;

- the handle is “free” to rotate at 360° thus allowing the ergonomic features to remain constant;

- the handle diameter allows the operator to wrap the tool with the hand and use the forearm muscle;

- the handle shape is not round as common handles to follow the operator hand anatomy;

- Additionally, the user can keep a neutral posture of the wrist performing the tasks.

What about the other IPC products?

All IPC products take care of user ergonomic requirements, such as:

It’s equipped with an adjustable handle through which the operator can reach all the areas to be cleaned. Loading and parking the machine, even in small spaces like the baggage area of a car, is now achievable. And with the reverse dry system, this mini scrubber dryer delivers fast drying in all directions, including in reverse, with easy and intuitive movements.

Both these models are provided with a foldable and adjustable handle which allows a good working position, compact storage and easy transport.

Their ergonomic design makes them easy to transport: the vacuums are provided with practical handles that allow the users to grab the tube and the handle with only one hand. Additionally, the cable wrap is also integrated to the handle.

Friendly, speedy and handy, the Cleano range are designed to solve window cleaning requirements. They feature telescopic anodised aluminium poles with a click–lock device and articulated joint which allow users to achieve cleaning tasks even in the hardest places, reaching up to 5 metres from the ground. Easy to use, lightweight, compact and manoeuvrable, Cleano can clean tight corners from any angle, washing and drying all surfaces while significantly reducing operating times.

There is no doubt that Ergonomics must be integrated into the business and management systems of any company.

Through Ergonomic standards application, lower MSDs accidents happen and achieve a general improvement of workers safety and comfort. Additionally, there’s a directly proportional relationship between the application of Ergonomics and the improvement of the quality process: if operators are satisfied and fine when working, their performances visibly improve and are optimized.