Estimated post reading time: 15 minutes

It is clear that every environment requires different procedures and cleaning systems and is also clear that the healthcare sector has very strict requirements and specific cleaning practices where operators must comply during their everyday activities.

A healthy, immaculate and tidy room with clean surfaces is very comforting to patients and their families, giving the impression of good quality care without risk of contamination.

That is why, although cleanliness is important in any economic sector, healthcare has a dual function of hygiene control and infection prevention.

In hospitals, private clinics, and health service structures, cleaning is a particularly important task and requires intensive and frequent activities, with a wide range of chemical products, detergents, and both automated and manual equipment.

General guidelines on cleaning in healthcare

- Cleaning is a process intended to physically remove microorganisms, particles of filth and grease from objects and surfaces. These actions are normally accomplished with the help of manual equipment (trolleys, mops, buckets, detergents, etc.) or machines (scrubber dryers, vacuums, steam generators etc).

- Cleaning is also a form of decontamination that makes surfaces safe to handle or use by removing organic matters, salts and soil, all of which interfere with microbiological inactivation.

- Disinfection describes a process that eliminates all pathogenic microorganisms, except for bacterial spores, on inanimate objects.

Therefore, it is now clear that cleaning in healthcare environments has a double task of cleaning and disinfecting at the same time. This dual action achieves the essential goal of preventing uncontrolled infections.

Every year hundreds of patients become affected by “hospital” infections worldwide, causing potentially dangerous epidemics and relevant financial losses to health systems.

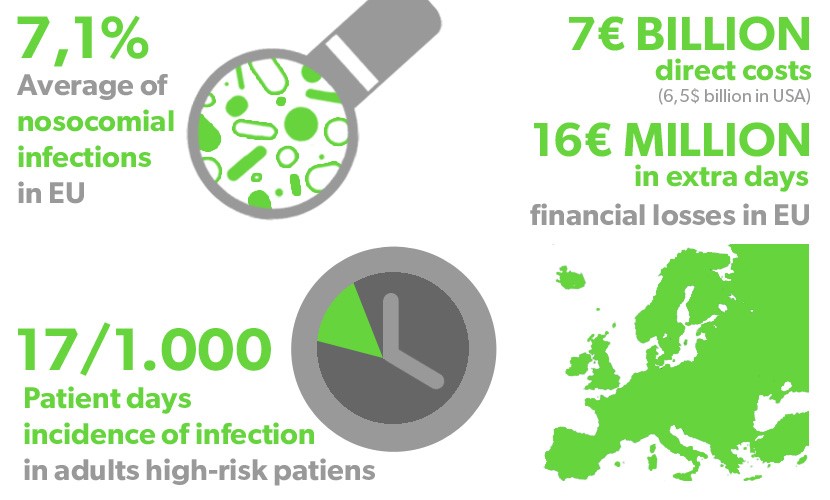

The prevalence of “nosocomial” infection in developed countries varies between 3,5% and 12% with an average of 7,1% in European countries.

The incidence of patients becoming infected in intensive care units can be as high as 51%; with an additional 30% of patients in intensive care units (ICUs) being affected by at least one episode of healthcare-associated infection. This means that the cumulative incidence of infection in adult high-risk patients is 17 episodes per 1000 patient-days.

It is also significant to underline that annual financial losses due to healthcare- associated infections are considerable: estimated at approx € 7 billion in Europe, including direct costs only and reflecting 16 million extra days of hospital stay and at about US$ 6,5 billion in the USA.

Are we sure that the equipment we are using is not contaminated?

All surfaces, including reception desks, tables, stair rails, floors, and elevators should be cleaned at least daily using effective detergents and warm water, rinsed and dried. It is recommended to dry all surfaces after cleaning, as moisture attracts contaminants and boosts microbiogical growth.

While training operators is a necessity and provides the staff with the basic rules to work efficiently in the healthcare sector, the right detergent and tool can definitely simplify and optimize the task.

For instance, a trolley equipped with the instantaneous impregnation system, is knocking down all bacteria proliferation and is a guaranteed antibacterial defense. The Smart Disinfection System is the only instant mop impregnation device that can be easily placed in a standard janitorial trolley.

Impregnation is instantaneous and the amount of solution is calibrated to the specific kind and condition of the floor. With a single push of a button on the control panel, the mop is immediately impregnated and ready for use.

The benefits of this system are: a 60% reduction in the use of chemicals, maximum effectiveness of active ingredients, no need to prepare mops in advance, re-use of mops that can withstand up to 500 cycles of washing machine and 15-20 weeks of standard cleaning with 5000 sprays.

Cleaning equipment and machines are subject to contamination as well.

That’s why a product made with antibacterial plastics can be the product you’ve always needed.

With this purpose in mind, IPC has developed the most advanced antibacterial plastic blend that drastically reduces the bacterial load and limits the spread of microorganisms in the environment. Tests on our antibacterial plastics were carried out reproducing actual working conditions and focusing on Staphilococcus aureus and Escherichia coli. The results confirm the antibacterial efficacy of our product in accordance with ISO/DIS 22196 (Plastics – Measurement of antibacterial action on plastic surfaces).

This innovative antibacterial plastic is available both in the vacuum range (GP1/27 HEPA IS05) and in trolleys range (Brix SDS models), thus avoiding waste of time and risks in having to sanitize equipment and maximizing productivity in standard risk areas.

IPC’s system of products and protocols takes preventive measures to limit the risk of transmission and reproduction of pathogenic microorganisms caused by moving healthcare equipments from one area to another. This is achieved by:

- The use of antibacterial plastic and microfibers

- Ergonomic features that make cleaning effortless

- No touch solutions in all work situations (no need to touch mops for the operator)

- Replacement of mops for each area and separate dusters for each individual patient unit

- Drawers with lids and nets to collect dirty clothes to be washed

Source: www.who.int/en/

For more information, or to provide feedback, please write to info@ipcworldwide.com.